| Client | uptownBasel |

| Site concept | Fankhauser Arealentwicklungen |

| Architecture | Fankhauser Architektur |

| Consulting deconstruction steel structure | SCE |

| Deconstruction steel structure | Aregger |

| Assembly of steel structure | Stamm Bau |

| Planning | 2022 - 2024 |

| Realization | 2024 - 2027 |

| Status | Under construction |

The Schoren site in Arlesheim provides a perfect illustration of the evolution from early manufacturing location through traditional industrial facility modified by structural change to what will be uptownBasel, an Industry 4.0 center of excellence. The idea for the new campus was originally the brainchild of architect Hans-Jörg Fankhauser, who first developed a concept for its use alongside investor Dr. Thomas Staehelin in 2017. Nine buildings totaling some 200,000m² of usable space are set to be built on the 70,000m² site by 2028. Key to the project is a commitment to the use of sustainable construction materials based on a circular economy model – in particular the reuse of steel.

A former military storage facility on the site played a key role in a project that was interpreted not as a demolition exercise but as a source of materials. The various components making up the building were in good condition. The load-bearing capacity of the foundations and basement was so high that they could be re-used in their entirety with only limited local reinforcement; there was no need to strengthen the existing foundations. Visual inspections revealed only minor corrosion, strength tests confirmed the quality of the materials, screwed and welded connections proved to be largely intact. The roof, on the other hand, was structurally inadequate with permissible loads of less than 100 kg/m. It was this discrepancy between structural quality and current building use regulations that generated the fundamental idea behind the project. Rather than opting for an extension, the decision was made to construct a new, four-story reinforced concrete structure on top of the existing basement and to supplement it with two new plant buildings.

As a result, instead of using conventional techniques, the facility, with its span width of 70m, was demolished stage-by-stage in an engineering-led process. Some 1300 metric tons of steel girders were tested, digitally captured, assigned QR codes and stored on-site for reuse.

The demolition was carried out with all the precision of a newbuild: overall stability had to be guaranteed throughout, constraints avoided and forces temporarily redirected. The bulk of the structural components were certified for reuse immediately; others were classified according to levels of corrosion and deformation and stored. Central to the process was the logging of all these elements in a materials database that provides information on beam cross-section, length and condition, storage locations, test reports and potential uses. There are currently some 1200 metric tons of dismantled steel stored on the site – steel that can be retrieved just like the data in the database.

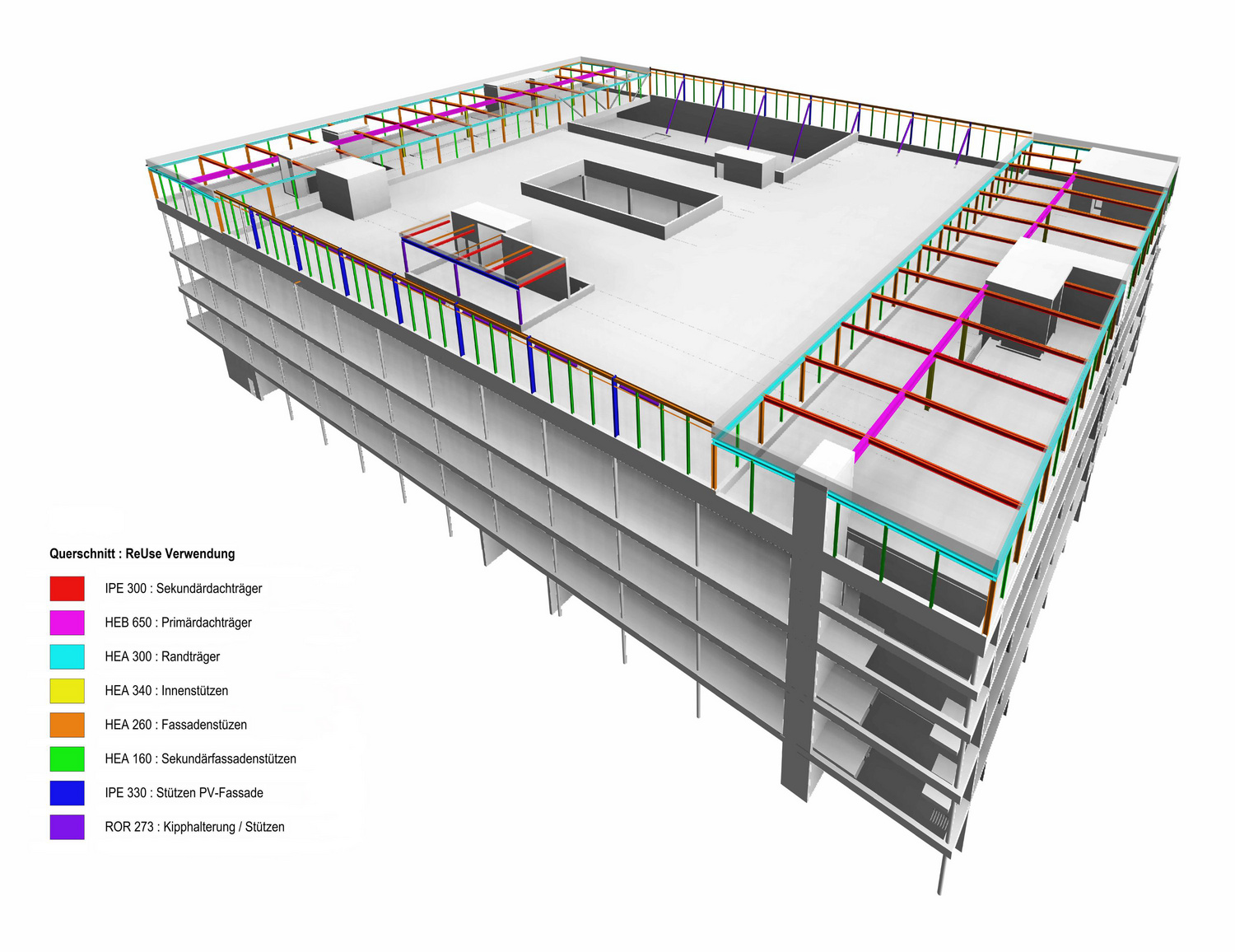

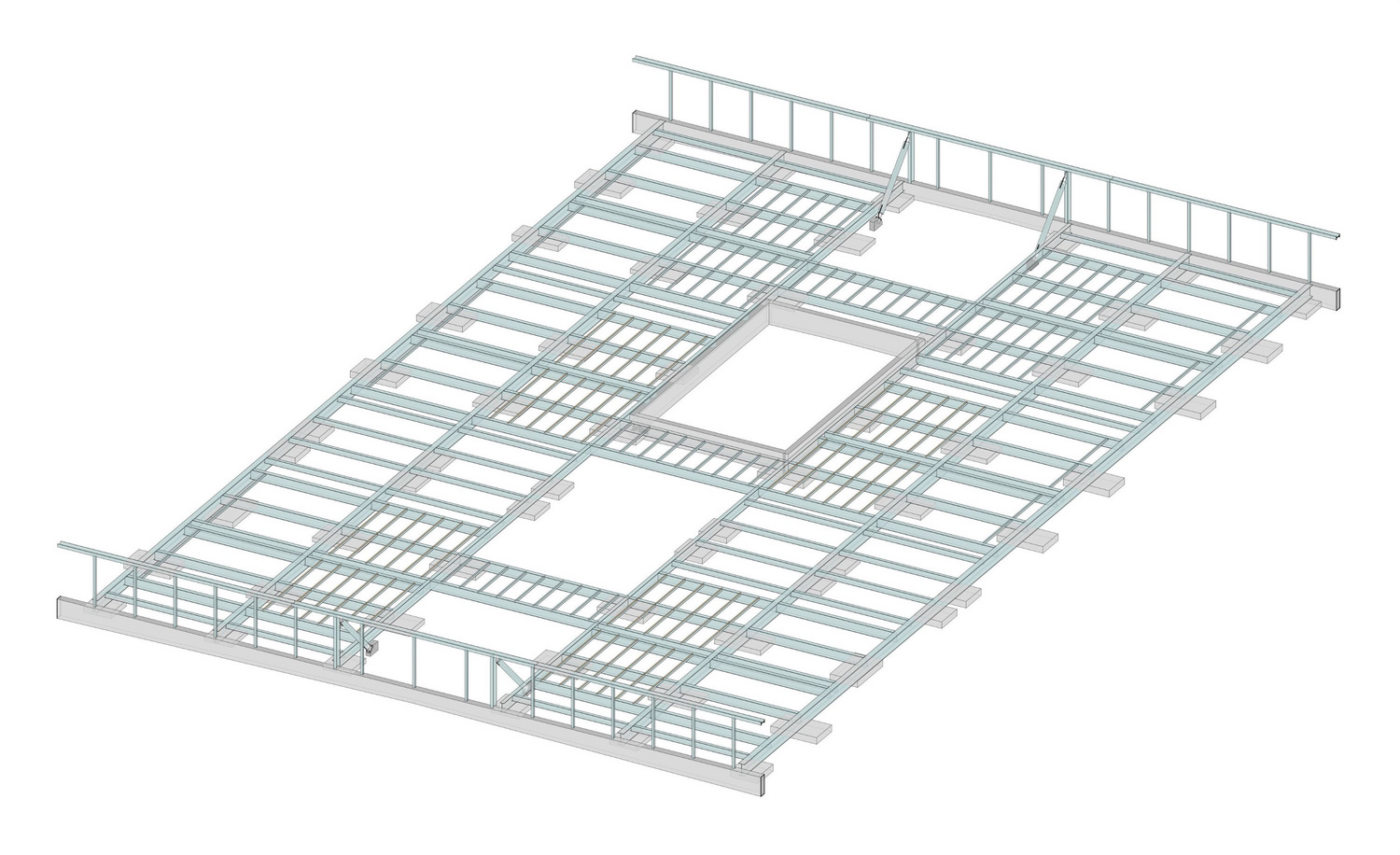

In Building 8, the planning team is working from suitable existing profiles, developing grids, span widths and load-bearing axes from the available components so that reuse is systemic, not simply based on identical components. More than simple add-ons, the old HEA, HEB and IPE beams form an integral part of new load-bearing concepts and in some cases are therefore able to carry greater loads than previously. Since the dimensions, quality and quantity of the steel available is known, the project is tailored to the materials rather than the other way around.

The high occurrence of certain girder profiles, in particular the industry-standard IPE 300 at approx. 60%, formed the basis for a modular construction system that allowed grid and construction heights to be designed to meet today’s requirements for office, commercial and residential use. The resulting standardization simplified both design and construction but demanded careful consideration on the part of the structural engineers. Despite their limited potential for reuse, welded connections are more structurally efficient than bolted joints and so continue to be a vital element in high-performance load-bearing structures. Instead of imposing constraints, the existing materials have created a new form of structural flexibility.

PUBLICATIONS

“Zweiter Einsatz für Stahl” from TEC21 11-07-2025 (in German)

© espazium.ch

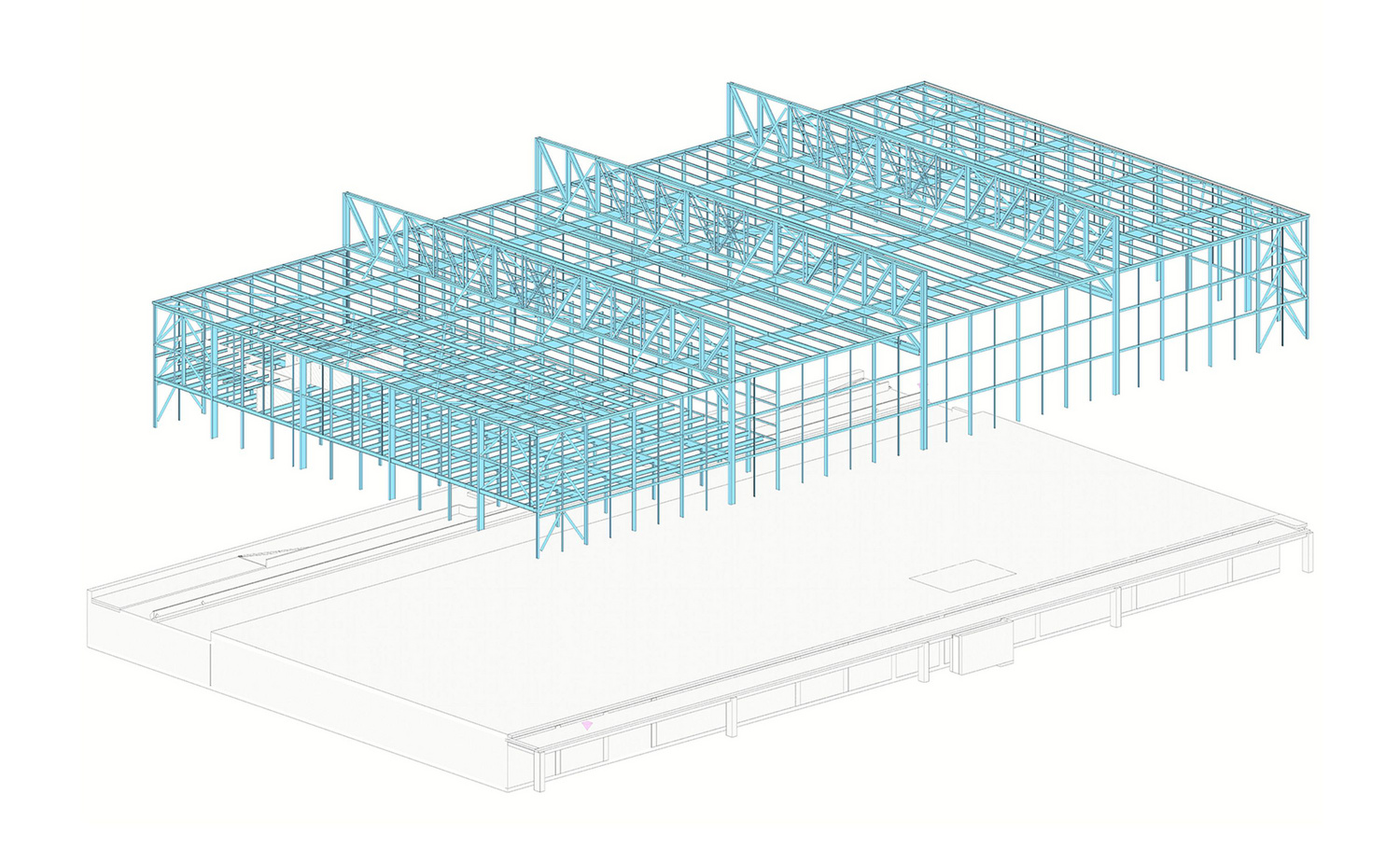

The former tank hall with its steel structure on the concrete basement.

Schnetzer Puskas Ingenieure

The former tank hall with its steel structure on the concrete basement.

Schnetzer Puskas Ingenieure

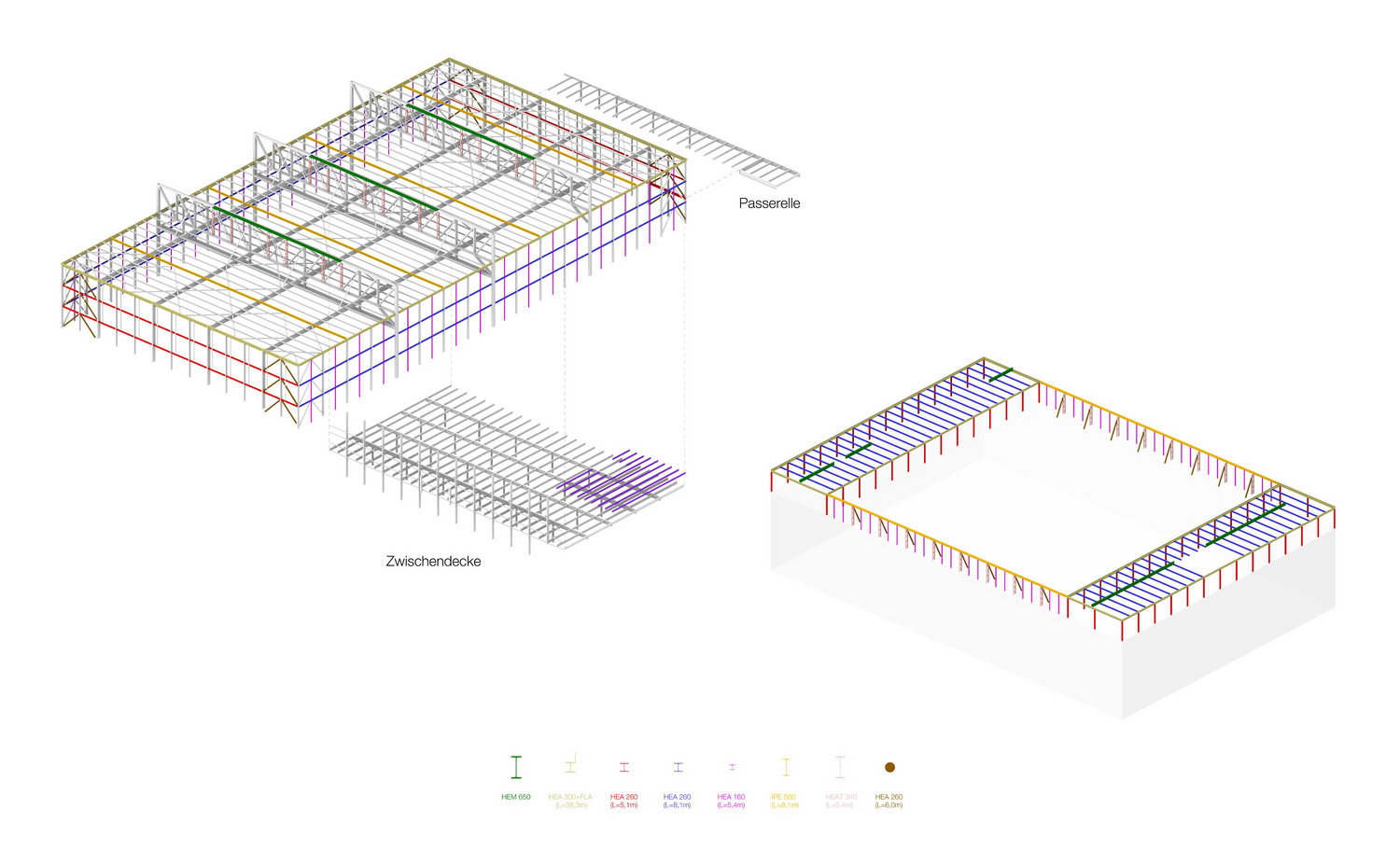

The existing building (left) and the reuse of steel in the new Building 8, top floor (right)

Schnetzer Puskas Ingenieure

The existing building (left) and the reuse of steel in the new Building 8, top floor (right)

Schnetzer Puskas Ingenieure

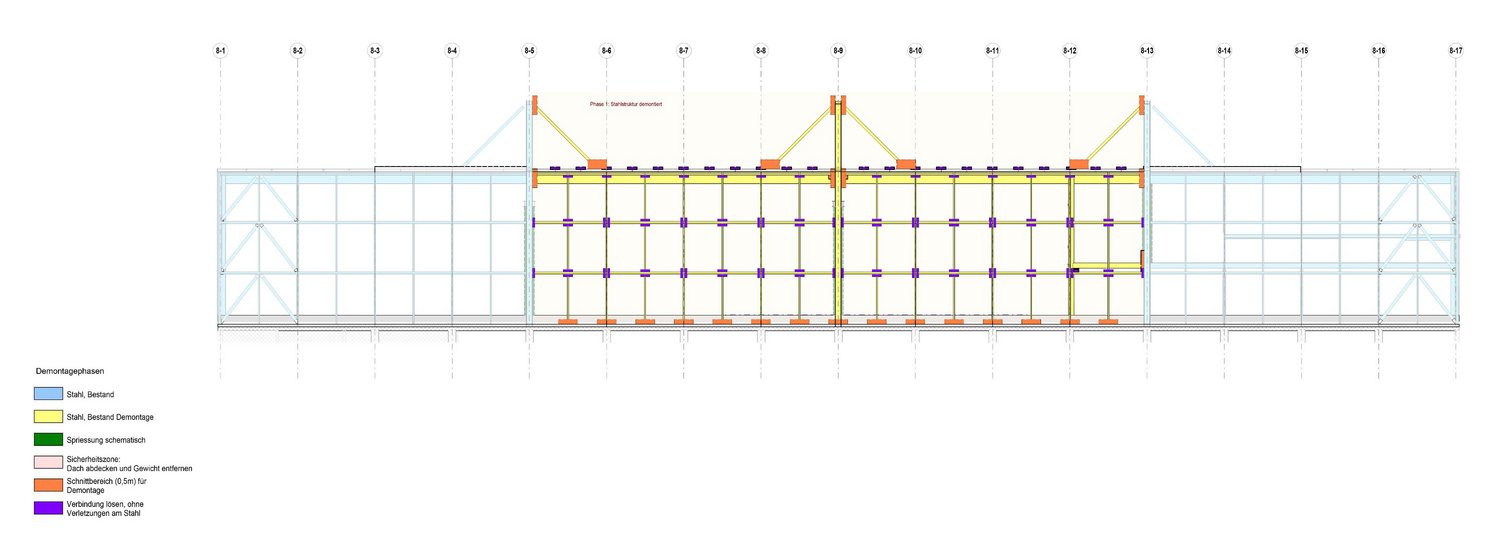

Disassembly procedure: Facade view

Schnetzer Puskas Ingenieure

Disassembly procedure: Facade view

Schnetzer Puskas Ingenieure

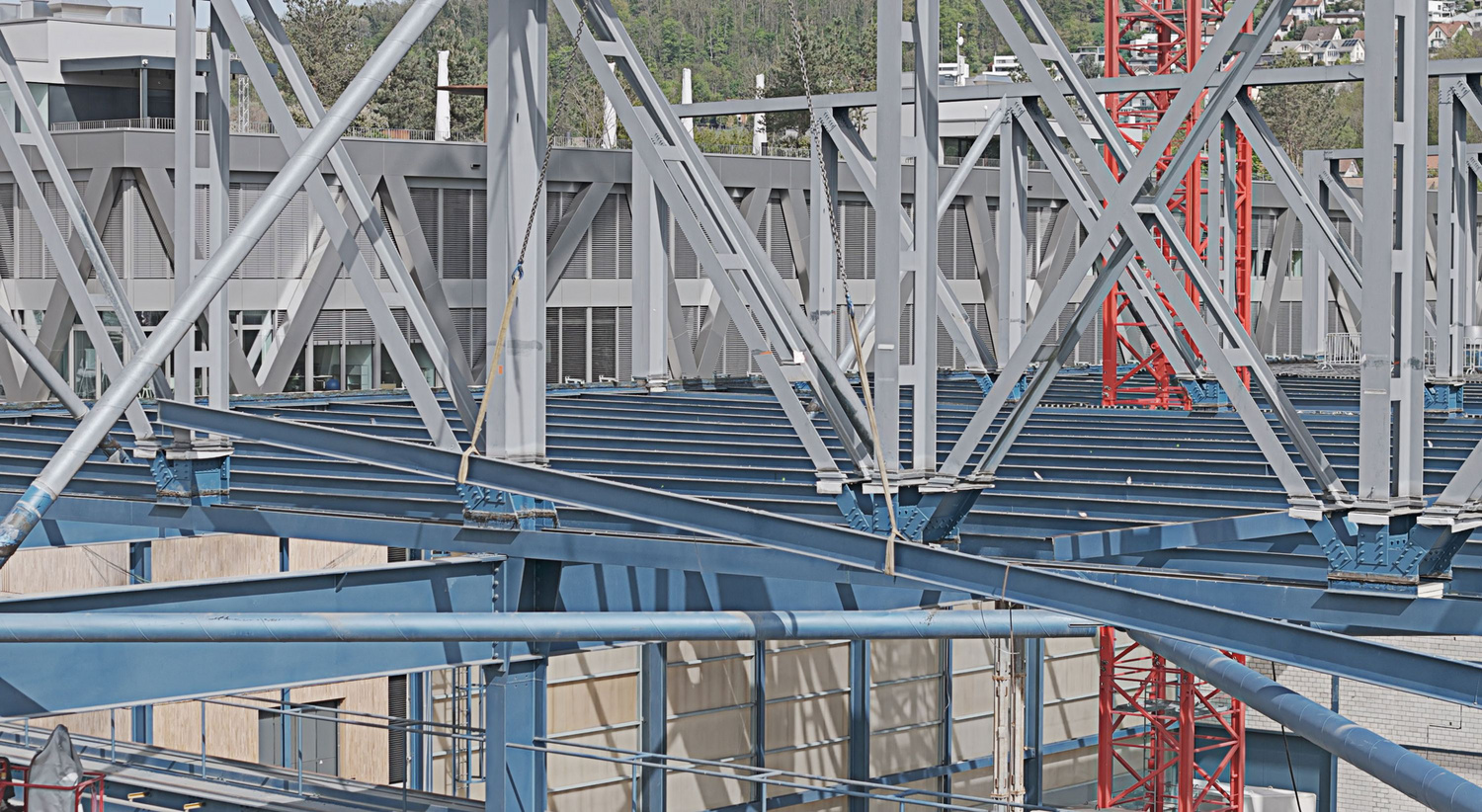

The new Building 8 with its roof structures.

Schnetzer Puskas Ingenieure

The new Building 8 with its roof structures.

Schnetzer Puskas Ingenieure

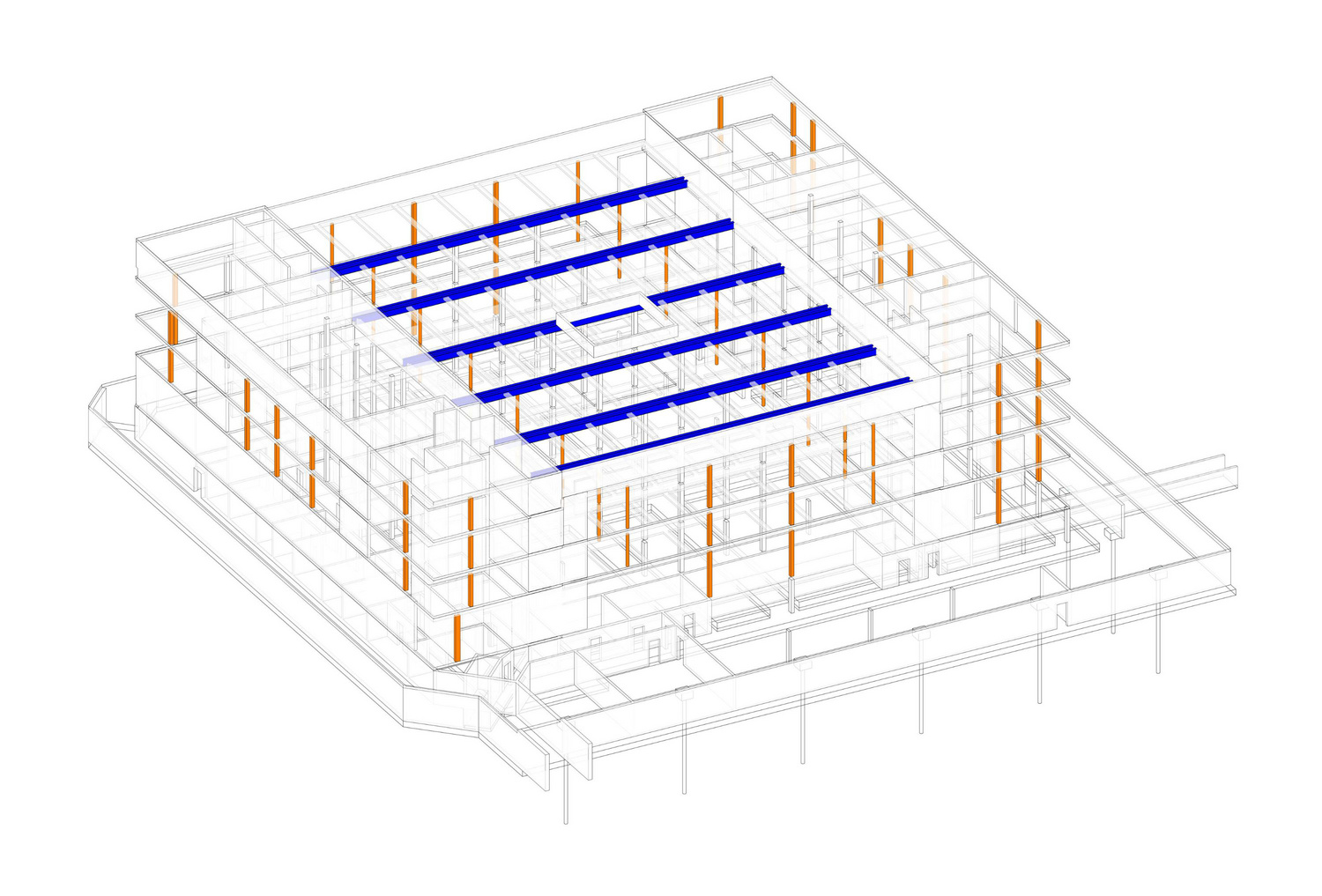

The used steel beams are being incorporated into the floors of Building 2 as composite beams.

Schnetzer Puskas Ingenieure

The used steel beams are being incorporated into the floors of Building 2 as composite beams.

Schnetzer Puskas Ingenieure

Building 2, 3D view of central steel structure on the third floor

Schnetzer Puskas Ingenieure

Building 2, 3D view of central steel structure on the third floor

Schnetzer Puskas Ingenieure

| Client | uptownBasel |

| Site concept | Fankhauser Arealentwicklungen |

| Architecture | Fankhauser Architektur |

| Consulting deconstruction steel structure | SCE |

| Deconstruction steel structure | Aregger |

| Assembly of steel structure | Stamm Bau |

| Planning | 2022 - 2024 |

| Realization | 2024 - 2027 |

| Status | Under construction |